Description

How it Works

Correct installation is crucial for the durability of any paving application. Here’s a brief guide to help ensure maximize the performance of your EZ Street material.

Material

Temperature & Compaction

EZ Street can be applied when air temperatures are between 0° F and 100° F; however, EZ Street will be most pliable, workable, and compactable at air temperatures ranging from 70° F to 90° F. In the winter months, warming of the EZ Street material prior to an application via a “hot box”, heated dump bed, or patching truck is acceptable; although, it is imperative that the material temperature does not exceed 125° F. To ensure optimum performance EZ Street should be applied and compacted in two-inch (2″) maximum lifts. A vibratory steel wheel roller will always provide optimum results and performance; however, steel wheel or pneumatic rollers, compactor plates, wheel rolling, and hand tamping are also acceptable methods of compaction. Over-compaction is rarely an issue.

Installation Procedure

To Achieve Optimum Results

SWEEP

Sweep out loose debris, dust, rocks—if it’s not fixed to the road, your patch won’t be either. (Water can stay).

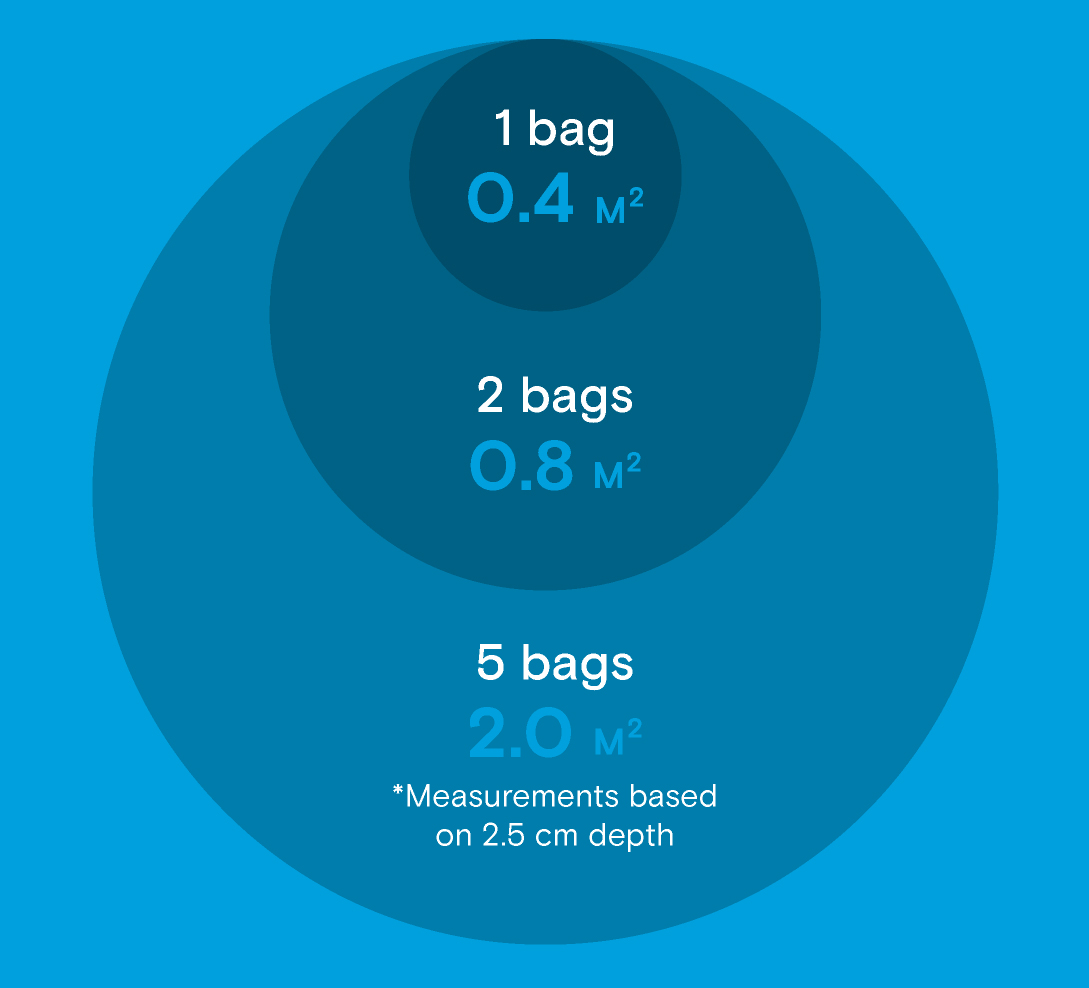

FILL

Fill the pothole to one inch above the surrounding surface. For craters deeper than four inches, apply EZ Street in two-inch lifts, compacting each layer before applying the next.

COMPACT

Shovels work. Tamps are good too. But the easiest method is simply driving over the repair a few times until it’s just about level with the road. Traffic will provide secondary compaction.